Tambour Doors

Tambors are sliding doors that can be very useful in certain furniture designs. They have a practical side — where there is not enough room to swing a hinged door, a tambour can slide open and expose the full width of a cabinet. And they are fun too, as they smoothly slide along, bend around a curve, and disappear into the cabinet.

We are going to design and build a case for a pair of tambour doors to understand their many aspects. Garrett will talk about tambour design, making a pattern for routing tracks for the tambour, different ways to shape and decorate the slats, how to connect them with a fabric backing, handles, curved interior partitions, and how to fine tune your tambours so they slide sweetly.

Precision with Hand Tools

I'm headed back to the Center For Furniture Craftsmanship for my 23rd year — hopefully not my last — for one of my favorite and most useful classes.

PRECISION WITH HAND TOOLS is a class to ramp up your hand tool skills — smoothing surfaces, jointing edges, fitting joints, cutting beads and curves. Only we’ll link those tasks to the reality of building a fun little table with lots of design possibilities. The Fun-O-Meter is going to be pegged.

We’ll use machines lightly where they work best — bandsawing legs and cutting mating mortises and tenons — but otherwise work by hand through a range of typical tasks hand tools do best: flattening, truing, shaping, and smoothing surfaces to a polish. We’ll talk about ways to integrate hand tools in your process, sharpening, tuning, and lots about design and detail. Our tables will be small, but they are an ideal project to hone some hand tool skills and try out some new design ideas.

PRECISION WITH PLANES — Lie Nielsen Workshop

Planes are essential to good woodworking for they can perform many tasks far more simply and often better than machines. Learning to use them effectively will improve your efficiency, accuracy, and above all your enjoyment of working wood.

Building any piece of furniture involves many different hand plane skills, the ones we will focus on, from flattening surfaces and smoothing them to a polish, cutting end grain, jointing long grain edges such as for joining two boards, fitting joints, shaping curves and simple molded edges, working to a pattern, fitting a drawer face to an opening, and cutting some useful details. And of course we’ll talk about sharpening and tuning your planes so they work as effortlessly and accurately as possible, and even about how to integrate planes in your process.

ELEGANT DETAILS

Details can add fun and interest to your furniture, plus they are practical — softening an edge or lightening the visual weight of some part. We will explore lots of practical details and techniques — at your pace — making delicate string or line inlays, cutting in surface inlays such as panels or diamonds, making patterned bandings, and using non-wood materials such as metal, shell, or bone. We will also focus on complementary moulded edges, chamfers, side beads and proud cockbeads used to highlight the edge of a table apron or drawer.

We will work almost entirely by hand, so naturally sharpening, tuning, and using hand tools will be discussed. We will also make some of our tools, amazing scratchstocks used to cut precise inlay grooves and small molded surfaces.

Curved Coopered Cabinet

Coopering — think of a barrel with individual staves joined together — is an efficient and interesting way to create three dimensional curved forms. We will work with straight staves, bevel them along their long edges to fit tightly against their neighbors, to build an elegant curved corner cabinet with a curved door. We will also fashion some moldings for our cabinets, and if you are really ambitious, you can build in a drawer too.

Construction of the cabinet before the staves are fit is not complex. It’s essentially glued and screwed together from the back, which is completely hidden once the cabinet is hung. I would strongly suggest you follow my plans the first time you build with this technique; for the next one you can taper the staves and see what challenges you run into.

The basic cabinet has a single shelf (or two and maybe a drawer between them), a top, and bottom. The rest of the case is three parts — two sides, and a narrow back. Beveling and fitting each stave is where the real work of the week lies.

MAKE AN OCCASIONAL TABLE WITH EXQUISITE DETAILS AND INLAY

England’s West Dean College is an amazing place to take a class, unlike no other. It’s 6000 acres deep in the rolling chalk hills of The Downs with grazing sheep, extensive arboretum, ornate outbuildings, and 12 acres of walled gardens, hothouses, and orchards. Everything centers on the huge manor house with classrooms and shops for woodworking, metalworking, drawing, pottery, weaving — from making to conservation. We work together and eat together, have tea in the afternoon and cocktails in the bar in the evening. It’s quite a posh place really.

So, about the tables we will build. They are an ideal project to explore some new ideas: inlays, a leg shape, table-top edge profile, top overhang, chamfers, curves, and apron details. We’ll build from start to finish, from drawings to the shellac, and end with an extremely useful critique of what we've made. The Fun-O-Meter will be high this week!

The tables I have in mind have uncomplicated joinery, with the slight twist the legs are splayed for aesthetic and stability reasons. Beyond that, you design the proportions and different aspects with my help and plenty of demos of the possibilities. Since the joinery is simple, you’ll have plenty of time to focus on the other parts and all-important details. We will talk about fitting a drawer into your table, but not build them.

Naturally hand tools will figure prominently, for efficiency, accuracy, and for the high quality work they are capable of. We'll also discuss ways of working, from using patterns to story sticks, producing useful drawings, construction strategies, alluring details, using different materials, and how to make some of the small tools you will need. We’ll have a wide-ranging conversation about building beautiful and useful furniture.

Tambour Doors

Tambors are sliding doors that can be very useful in certain furniture designs. They have a practical side — where there is not enough room to swing a hinged door, a tambour can slide open and expose the full width of a cabinet. And they are fun too, as they smoothly slide along, bend around a curve, and disappear into the cabinet.

We are going to design and build a case for a pair of tambour doors to understand their many aspects. Garrett will talk about tambour design, making a pattern for routing tracks for the tambour, different ways to shape and decorate the slats, how to connect them with a fabric backing, handles, curved interior partitions, and how to fine tune your tambours so they slide sweetly.

Fine Woodworking LIVE

Design Details that Dazzle

I’ll be giving this talk twice during the event.

Creative details will enrich your work and add dazzle to your designs, but they also often have a practical purpose—softening or protecting an edge, lightening the visual weight of a part, or disguising a joint. This session will focus on chamfers that highlight an edge, incised beads and cockbeads that outline and beautifully round an edge, simple inlays that pop, and shaped surfaces that have tactile appeal. You’ll learn the best ways to incorporate these ideas into your work, plus Garrett will demonstrate how to use hand tools to create the most polished details right off the tool.

Cabinet Curiosities

UNFORTUNATELY, THIS CLASS HAS BEEN CANCELLED

Case construction is a fundamental furniture making skill. Designing and building a small cabinet is an ideal project to explore the design, details, and challenges of solid wood construction before starting on much larger casepieces. We’ll delve into strong case joinery, choosing appropriate materials, dealing with wood movement, securing shelves and backs, making and attaching moldings, case corner details, making and hinging doors, and if we have time, making drawers. Emphasis will be on hand skills and hand tools to size, smooth, shape, and fit parts. We will also integrate machines to make the building process efficient and accurate.

HANDS ON Tampa — Fine Woodworking Elegant Details

Creative details will enrich your work and add dazzle to your designs, but they also often have a practical purpose—softening or protecting an edge, lightening the visual weight of a part, or disguising a joint. This session will focus on chamfers that highlight an edge, incised beads and cockbeads that outline and beautifully round an edge, simple inlays that pop, and shaped surfaces that have tactile appeal. You’ll learn the best ways to incorporate these ideas into your work, plus Garrett will demonstrate how to use hand tools to create the most polished details right off the tool.

Working with Curves

The Florida School of Woodwork is a new school for me, in a vibrant area of Tampa. Of course being in Florida in February should be lots of fun.

As your woodworking skills develop, so does a natural interest in designing beyond the straight and square. Curved shapes can add elegance, allure, and even strength to your furniture designs. We will explore and make several different curved parts: by laminating for curved drawers and chair parts, by shaping out of the solid with hand tools, by coopering (think barrel) for curved panels or case sides, and finally by steam bending.

We will talk about how to generate pleasing curves, draw them full scale (for the joinery later), make quick patterns, bending forms, and laminates. How do you decide the best technique for producing those curved parts, and then proceed in an efficient and successful way? We'll go through as many processes as we can, including some interesting hybrids. Your challenge will be to produce some accurate parts and join them together with strong joinery.

Arrive at the class with some ideas of what curved construction you would like to experiment with — a curved drawer face, curved table rail, curved parts for a chair, or a coopered curved surface (case or door panel).

Casework Essentials

Case pieces nearly anything with some drawers or doors are one of the most common furniture forms makers design and build. We are going to explore the fundamentals of casework by designing and building our own small cabinets in solid wood.

Think about this project as a "study" piece a place to try out some new design ideas while learning the basics of good case construction. You will undoubtedly refer to your cabinet many times in the future to better understand shelves, drawers, doors, case backs, moldings, secret compartments, and a whole lot more.

Demonstrations and discussion address topics such as as strong case joinery, choosing appropriate materials, working with solid wood and wood movement, building drawers and how to support them, fitting and hanging doors, along with lots of fun details for edges and surfaces. A constant theme will be elegant and efficient design.

Naturally our emphasis will be on using hand tools for their effectiveness and enjoyment. We will size, smooth, shape, and fit parts with planes and other tools, but also integrate machines to make the building process efficient and accurate. And we are going to have a lot of fun constructing casepieces that will inspire many other projects you will certainly go on to build.

.

Tambor Doors

Back for my tenth or eleventh year teaching for DICTUM, an amazing tool dealer with a calendar of classes far more diverse and intriguing than anywhere else I know about. The students are diverse as well, mainly from Germany, but often from elsewhere in Europe. I’ll be teaching two week-long classes, first in the small town of Niederalteich, about an hour out of Munich, and the second week at their new workshop in Munich.

Tambors are fun sliding doors that are less commonly used today, although they should be. They can slide around a corner and completely disappear into the case or cabinet they are built into. In a situation where there is not enough room to swing a hinged door, quite likely a sleek sliding tabor can do the same task. We are going to build small cases and play with some different sliding tabor designs.

PRECISION WITH HAND TOOLS

PRECISION WITH HAND TOOLS is a class to ramp up your hand tool skills — smoothing surfaces, jointing edges, fitting joints, cutting beads and curves. Only we’ll link those tasks to the reality of building a fun little table with lots of design possibilities. The Fun-O-Meter is going to be pegged.

We’ll use machines lightly where they work best — bandsawing legs and cutting mating mortises and tenons — but otherwise work by hand through a range of typical tasks hand tools do best: flattening, truing, shaping, and smoothing surfaces to a polish. We’ll talk about ways to integrate hand tools in your process, sharpening, tuning, and lots about design and detail. Our tables will be small, but they are an ideal project to hone some hand tool skills and try out some new design ideas.

DRAWERMAKING

We are going to build some sweetly running drawers. But to really understand about fitting drawers, you need to have an accurate and strong case to support and guide them. So we'll make that case, which is a fun project in itself.

Drawers can be built in a nearly unlimited variety of sizes, shapes, and ways they are supported. We’ll explore the best of these variations, along with dovetails, using solid wood bottoms, determining the thickness of the various parts, and dealing with seasonal wood movement. Most of these ideas can be distilled to a simple and elegant drawer design that works for nearly every situation. We’ll build one or two such fine drawers, ones that can serve as models for every drawer you go on to build.

CHAIRS/DETAILS 201

For my 16th year teaching at Rosewood Studio, in the beautiful town of Perth, Ontario, two classes.

CHAIRS

Chairs are enough of a challenge that many woodworkers avoid building them. So let's be honest, a week class isn’t long enough to complete a chair, at least not one you would be happy with. But we can explore many aspects of making chairs such as comfort, elegance, and strength.

Your work will be drawing, making parts, and cutting joints for your own prototype chair. My goal is to teach you the necessary skills so that you understand how to go about designing an attractive and comfortable chair, draw it full scale and use that drawing to produce patterns and shape parts, and then engineer and cut durable joints to join it all together. I want you to know which materials to use, critical dimensions and angles, about steam bending and laminating to make extra strong curved parts, and even about making a seat frame for upholstery. I’ll bring along a started chair and use it to illustrate some of these important ideas.

````````````````````````````````````````````

Saturday/Sunday June 29/30

DETAILS 201

Let’s assume you know how to make a scratchstock, can make a clean inlaid line (a string inlay), and have some experience with inlaying pieces into a surface. Hopefully you have taken DETAILS 101, but if not we can do a quick refresher before we explore and expand on these basic techniques.

We can try some curves (against a pattern), some new ways to highlight an edge with a diagonal or solid wood inlay, use bone, shell, and metals, and create some fans or other shapes to inlay. We will do a lot with panels inlayed at the top of a leg or into a tabletop, since they are particularly good places to creatively combine different materials. And we could make some complex bandings. There is so much to explore, what are you are curious about?

We will work almost entirely by hand, so naturally sharpening, tuning, and using hand tools will be an important emphasis. We will make small sample boards to practice designing and using these decorative techniques. Bring along any interesting materials you would like to use, and I’ll have some on hand too.

Fine Woodworking LIVE

Fine Woodworking’s annual LIVE gathering of woodworkers, with classes, demonstrations, tools and lots more for sale, and plenty of opportunities to meet and talk.

I am giving a class about building strong, light, and stable CURVED DOORS, using a traditional technique with a solid staved core overlaid with layers of veneer. I am also giving a morning presentation on DEVELOPING AN EYE FOR DESIGN, which I liken to a visit to a really good furniture museum with an insightful curator.

Annapolis Woodworkers Guild

Friday, April 12th, all day

PRACTICAL DESIGN

Good design isn’t simple; it’s by far the most challenging part of building furniture. One of best ways to become a better designer is to look at and make sense of furniture that appeals to you. Guided by furniture maker Garrett Hack we will look at many images of furniture from antique to contemporary to understand what makes a design great — or not so great. How do you use proportion, line, shape, detail, contrast, color? Where do you start the process of designing something, what materials do you use, which joinery or other techniques do you build it with, and what details might enhance the work.

Beyond looking at images we will consider ways to generate pleasing curves getting started, making full scale drawings, how to choose the best wood for the project and organize your cuts for economy and quality, and how to develop a construction strategy for working accurately and efficiently. It all adds up to good design.

Saturday/Sunday April 13/14 HANDS-ON workshop

PRECISION WITH HAND TOOLS

Good hand tool skills allow you to work more efficiently, accurately, and enjoyably. We will practice many practical hand tool techniques typical to building any piece of furniture — flattening surfaces and smoothing them to a polish, cutting end grain, jointing edges such as for joining two boards, cutting and fitting some joints, cutting beads and curves, and simple molded edges. We will even make a hand tool, one so simple and effective that it will amaze you with its range of uses. And of course we’ll talk about sharpening and tuning your tools so they work as effortlessly and accurately as possible, and even about how to integrate hand tools and machines in your process.

Howard County Woodworkers Guild, Columbia, Maryland

The Howard County Woodworkers Guild has invited me to present some of my favorite subjects — design, using hand tools, details, and more. It should be informal and fun.

Contact Joel Lafferriere: ferrij3@verizon.net

NWA Showcase

Every spring the Northeast Woodworkers Association has a huge exhibition of member work and a woodworking show in wonderful downtown Saratoga, New York. You can find inspiration, woodworking classes, old and new tools, wood, supplies, and lots more.

I’ve participated many times over the last 20 years and have been invited back. I’ll be doing 2 classes each day on:

5 ESSENTIAL HAND PLANE TECHNIQUES

Hand planes are highly efficient, accurate, and for some work superior to machines. We’ll do some edge jointing, smoothing, fine true the shoulders of a joint, and a few other techniques that will persuade you to get out your hand planes and use them.

DAZZLING DETAILS

Details can be fun and add interest, but they are also practical — softening an edge or lightening the visual weight of a part. Garrett will demonstrate some of his favorite dazzling details, from fine inlaid lines to beads and proud cockbeads, and a little about using shell and metals.

Elegant Details

Details can be fun and add interest, but they are also practical — softening an edge or lightening the visual weight of a part. We will explore lots of practical details and techniques — at your pace — making delicate string or line inlays, cutting in surface inlays such as panels or diamonds, making patterned bandings, and using non-wood materials such as metal, shell, or bone. We will also focus on complementary moulded edges, chamfers, side beads and proud cockbeads used to highlight the edge of a table apron or drawer.

We will work almost entirely by hand, so naturally sharpening, tuning, and using hand tools will be discussed. We are even going to make some of those hand tools, amazing scratchstocks used to cut precise inlay grooves and small molded surfaces.

Practical Furniture Making

I’ve been invited by the Central Florida Woodworkers Guild to give a weekend seminar on what I call PRACTICAL FURNITURE MAKING, followed by a 2 day class on ELEGANT DETAILS.

Why are some pieces of furniture so appealing, elegant, and well made? Design is a factor, but so are the many choices the maker makes, which techniques, joints, woods, and details. We will explore this building process, looking at design, hand tools, strong joinery, wonderful details, and how to work efficiently and accurately — practical stuff and very useful.

Any related topic is fair game....... and we will have lots of fun.

Spinner Table (again)

A repeat of the previous week, in DICTUM's workshop in Munich.

For either class contact me or renate.schwarz@dictum.com

Santa Rosa Woodworkers

PRACTICAL FURNITUREMAKING

Why are some pieces of furniture so appealing, elegant, and well made? Design is a factor, but so are the many choices the maker makes, which techniques, joints, woods, and details. We will explore this building process, looking at design, hand tools, strong joinery, wonderful details, and how to work efficiently and accurately — practical stuff and very useful.

We start by looking at lots of images of well designed furniture and talk about design. From there we explore some important hand tool techniques which are efficient, accurate, and enjoyable. We will use them to cut two essential joints — a mortise and tenon and a tapered sliding dovetail. We finish with a focus on the DETAILS that can really add delight and pizzaz to a piece.

Contact me for more information.

San Diego Fine Woodworkers Association Fall Seminar

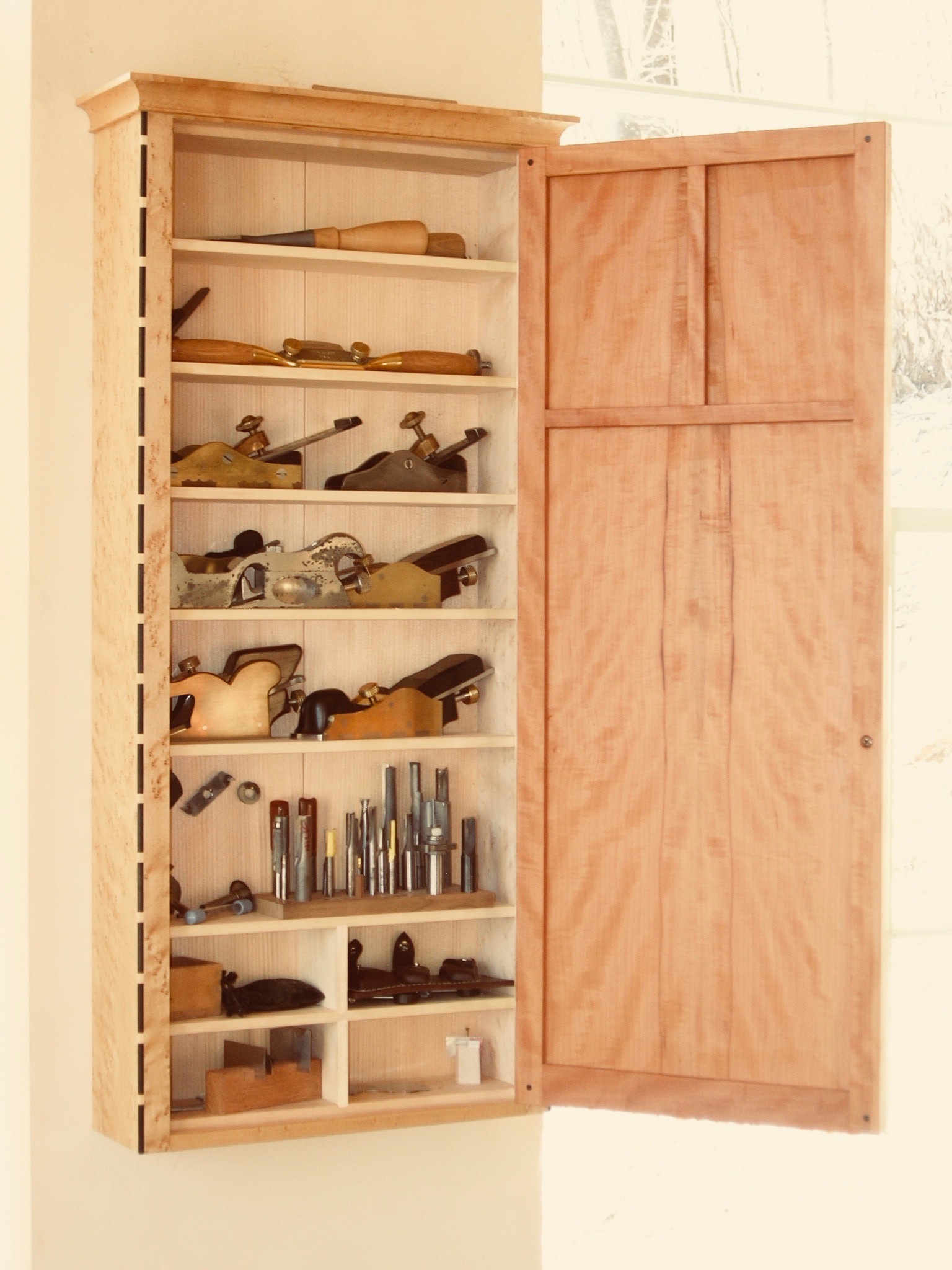

During this three day seminar I'll be designing and building a small hanging cabinet in front of a large crowd while explaining my process and answering questions. Although I have made many similar cabinets, I return to it as a teaching tool because it contains so many lessons about good case construction — an essential furniture form. The ideas can be expanded and used for a large chest of drawers or a whole variety of other case pieces.

Topics to be covered include: How do you build a strong cabinet simply and efficiently, choose appropriate materials, build with solid wood and allow for seasonal wood movement (yes, even in California they have to deal with this), build in drawers and the structure to support them, make a strong case back, and build and hang a door with butt or knife hinges? I will also show some appropriate decorative details such as moldings at the top and bottom, highlighted case corners, and shelf edges. I might even be able to include a secret compartment.

Naturally hand tools will figure prominently in this demonstration, which ones to use, how to tune them, and how I use them efficiently for the work at hand.

CURVES

This workshop will explore four techniques for producing curved parts —various types of laminations useful for curved drawers and chairs, shaping out of the solid with hand tools, coopering for curved panels or case sides, and steam bending One of the first questions we will answer is which method should I use?

Day one we will do some steam bending while we talk about making forms, what woods bend well, what tools are needed, and how to do it all simply. We will also glue some curved laminations, a slow but sure way to make very strong curved parts from any wood.

Day two we will cut some shapes from solid material such as a table or chair leg. Your challenge will be join your curved part to another, after first making a full scale drawing. Coopering and some of the interesting shapes possible with this technique will finish out the day.

Coopered corner cabinet

Typical lamination, yielding strong and light curved parts

PRECISION WITH HAND TOOLS

I'm headed back to the Center For Furniture Craftsmanship for my 22nd year — hopefully not my last — for one of my favorite and most useful classes.

PRECISION WITH HAND TOOLS is a class to ramp up your hand tool skills — smoothing surfaces, jointing edges, fitting joints, cutting beads and curves. Only we’ll link those tasks to the reality of building a fun little table with lots of design possibilities. The Fun-O-Meter is going to be pegged.

We’ll use machines lightly where they work best — bandsawing legs and cutting mating mortises and tenons — but otherwise work by hand through a range of typical tasks hand tools do best: flattening, truing, shaping, and smoothing surfaces to a polish. We’ll talk about ways to integrate hand tools in your process, sharpening, tuning, and lots about design and detail. Our tables will be small, but they are an ideal project to hone some hand tool skills and try out some new design ideas.